This photo shows a broken jack; the jack allows the hammer to "escape" from the piano key. Well, it's complicated, but without a jack when you press a key, the hammer just wacks against the string and stays there--"THUD"! I have two broken jacks--one came broken when I got it, and I broke one when I roughly removed the keys for refinishing.

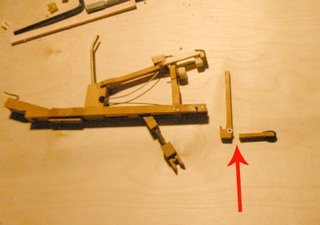

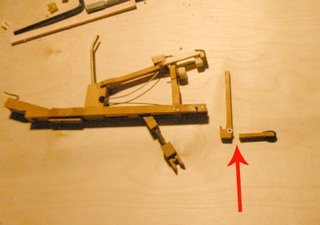

Shown here is my Lie-Nelson dowel press, along with a jack component that I made with the dowel press. The dimension of the tiny dowel that stick off of the end of the dowel jack is 1/8 of an inch. Very tiny, very hard to see and very hard to work with.

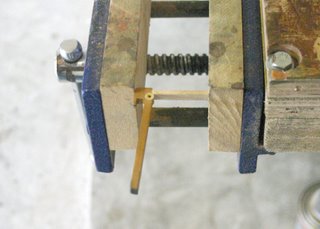

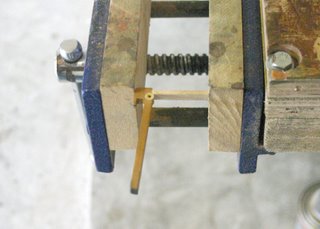

Here is the other half of the jack into which the dowelled portion is glued and inserted.

And here is the dry-fit jack reassembled next to an original jack.

Glued and drying...

The reassembled Whippen, with the repaired jack installed.

2 comments:

Michael, I am so lucky that 61428 had no broken parts. Ebel Hammmers in Germany, broke one during the re-felt and re-leather operation, but they replaced with new hammer and shank. The new soundboard is complete, lateral ribs could be saved, the longitudinal rib had to be laminated, glued up and bent in a homemade clamp. Bridges are precisely located on the new board to be glued up next week. The new board will be installed be installed first week of Feb. danfahr@q.com

nope don´t change the soundboard, its a vital original part, makes the sound of the piano, instead flipoter, you scrap the crack and put in a piece of wood in triangular shape so it tensions the soundboard again !!!!! People, these are 150 year old pianos, important pieces of history, you can´t just start a "restoration" you need to have knowledge first.

Post a Comment